When it comes to the world of transportation, unfortunately, truck problems are a necessary evil. The trucking industry topped $726.4 billion in revenue in 2015, according to Trucker Path, but the longer your truck is down with an issue, the more money that will be lost concerning both revenue and your own personal paycheck. Some of the most common kinds of breakdowns for semi trucks components are related to brake failure, electrical system failure, or engine failure. Here is a list of the top five issues that are most often damaged on commercial trucks.

Tires

By far the most damaged component on trucks are the tires. This is usually due to poor maintenance practices, including having not enough inflated tires dispatched under loaded trucks. Issues with tires account for a full 25 percent of the road calls made every year. Currently, this issue is being addressed with the implementation of automated tire inflation systems within the major fleets.

Brakes

Another major cause of roadside assistance is brake-related problems. Brake issues are among some of the most dangerous kinds of malfunctions, according to Truck Master Warranty, and are likely to induce an out-of-service citation, meaning a call-out before the vehicle can move again. Some of the most common problems that cause brake issues are:

- Air pressure leaks

- Reduced foundation brake performance

- Internal water and contamination in the air supply

- Oil passing from the compressor

- External corrosion and contamination

- Brake system pressure and timing imbalance

- Ineffective maintenance practices

Regular and consistent brake inspections as a part of a daily preventative maintenance routine are recommended to avoid these types of problems.

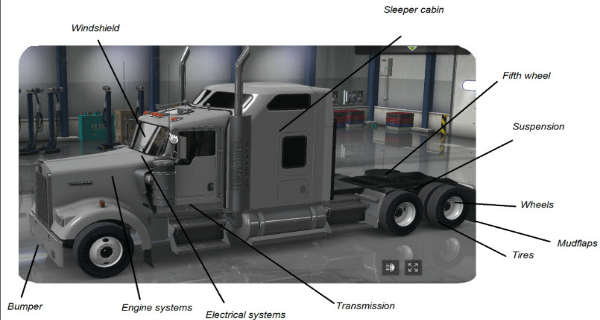

Electrical Systems

The cranking system, charging system, and lighting are all problems that can cause electrical issues. When considered together, electrical problems fall right behind brakes in terms of frequency. Over the last several years, electrical issues in semi-trucks have been on the rise, with cranking and lighting problems seeing an increase. Part of the problem stems from a reduction in idle time and an increase in loads due to driver comfort requirements.

Clutch Failure

Due to the high pressure on clutch cables, many times the wires will weaken and then ultimately break. Since the clutch is what controls the power from the engine to the transmission, an issue with this component can cause serious issues. As soon as you realize that you have a problem with your truck’s clutch, you should get a quote from Dynatect for a new mechanical slip clutch to protect your truck from mechanical overload.

Cooling Systems

Semi-truck cooling systems have long been one of the primary reasons for roadside assistance calls. The issue with these systems is almost always a result of the connections. The more connections a truck has, the higher the potential for loss of coolant, which is the primary failure mode associated with the cooling system. Using long-life coolants, premium hoses, and the best clamps, along with highly trained technicians, can help deal with issues before they become significant problems.

Dealing with damaged truck components when you are trying to make your delivery date is never a fun prospect. Making sure your truck undergoes regular inspection and preventative maintenance will help to reduce the amount of time you spend on the sideline.