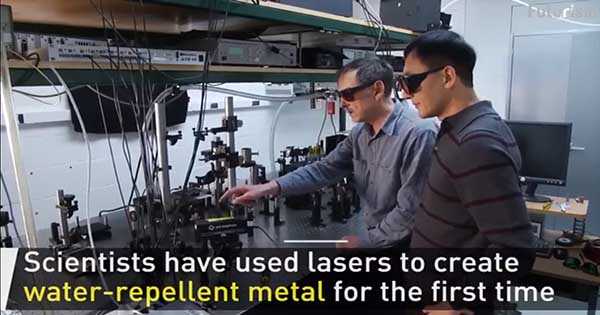

The scientists at the Rochester University used lasers in order to convert metals into super-hydrophobic or water repellent metal. This is done without the need of temporary coatings. These super-hydrophobic materials can be used for a variety of applications like anti-icing, rust prevention, or sanitation uses. These metals are now so super hydrophobic which makes water to bounce right off them.

The material makes water to run off it easily because it’s more slippery than even Teflon. Just imagine how efficient this would be for creating solar panels. So, if you thought that your Teflon-coated pan is efficient at repelling water, thing again.

This material is made by using lasers that etch microscopic patterns converting them into metal. These laser pulses last only an extremely small part of a second. However, it reaches power equal to the whole North American power grid.

Unlike Teflon, this water repellent metal is super-hydrophobic and the water also collects any dust particles thus cleaning the surface. They put this self-cleaning feature by taking ordinary dust from inside a vacuum cleaner.

They dumped the dust onto a surface. Nearly half the dusty particles were cleaned with using only three simple drops of water. It took just a dozen water drops to make the surface spotless. However, besides leaving the surface clean of dust, it was also made completely dry.

This means that the coat pans of the future are extremely easier to wash. That said the future holds many exciting this for us that will make all of our lives way easier.

Finally, read more about Pulsed Laser here!